Westernplow MARAUDER™ POLY P150A

|

|

|

Specifications

|

Model |

MARAUDER™ POLY

|

Category Name |

Snow Equipment

|

Year |

2025

|

|

Sale Type |

New

|

Manufacturer |

Western

|

Model |

P150A

|

|

Spinner Size |

16" Diameter

|

Bed Length (B) |

80"

|

Rec. Bed Length |

74"

|

|

Spreading Width |

Salt: Up to 36'

|

Body Side Length |

7'

|

Capacity (Volume) |

1.5 cu yd

|

|

Capacity (Weight) |

3,240 lb

|

Hopper Length (A) |

96.50"

|

Hopper Construction |

Polyethylene Body, Stainless Steel Drive Line

|

|

Vehicle Compatibility |

¾ or 1-Ton Pickup, Dump Body, Flatbed, or 15,000+ GVWR Truck

|

Material Compatibility |

Bulk Salt, Pre-Wet* & Liquid Brine*

|

Approx. Weight** (Empty) |

673 lb

|

|

Overall Hopper Length (C) |

108.25"

|

Factory Chute Configuration |

Short

|

Width Of Hopper Opening (D) |

63.50"

|

|

Material Delivery Dimensions |

6" Diameter

|

Height Of Hopper W/o Chute (E) |

46"

|

Price |

Contact for price CAD

|

|

|

|

Description

READY FOR ANY STORM

When the snow is flying and temperatures are plummeting, you need to be as efficient as possible. The MARAUDER line of hopper spreaders expands to give you the options you need to maximize efficiency. Corrosion-resistant polyethylene models with your choice of pintle chain or the ALL-NEW HELIXX™ auger delivery system are added to the MARAUDER line for more options to fit your operation’s needs.

|

|

|

|

UNIQUE FEATURES

|

Unique_features

|

Polyethylene Construction & Geometry

Resist the corrosive environment of de-icing with polyethylene construction. Lightweight, yet highly durable, these hoppers are built to last. The molded polyethylene tub geometry is optimized for better material flow. This allows for a smoother, even flow that prevents materials from getting stuck.

|

|

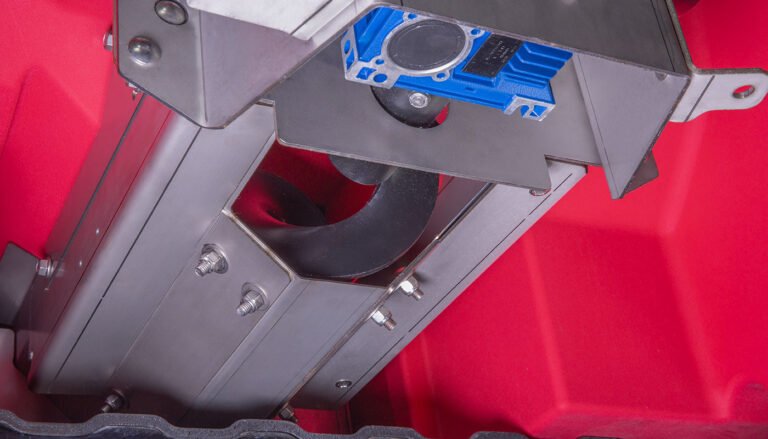

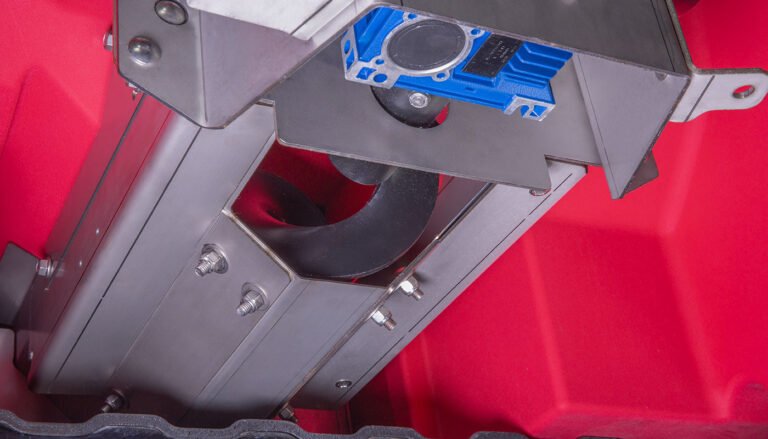

HELIXX™ Auger Technology

Patented corkscrew material delivery system is optimized to operate in the target range for rock salt spreading best practices. The auger has multiple pitches to help promote smooth, even material flow from the hopper and prevents bridging. The shaftless technology reduces drag on the motor and reduces the overall load on the electrical system.

* Auger Models Only (P150A & P220A)

|

|

Pintle Chain Conveyor

The large conveyor delivers reliable, smooth, and consistent material flow for heavy, dense materials (like sand and 50/50 mix) while reducing bridging.

* Chain Models Only (P150C & P220C)

|

|

Interlocking Poly Lids

Standard lids have molded channels for moisture runoff. Pockets at the end of the lid allow a 2×4 to be inserted for leverage while opening.

|

|

Stand on End

Special design allows the hopper to stand on end for easier storage in the off-season and easier installation into the truck bed. Simply remove the two pins, unplug it, and take off the chute before standing up the hopper.

|

|

Extended Material Delivery & Pre-Wet Chamber

A material delivery extension reduces leaking/ spilling during transport and leads into the patented pre-wet mixing chamber. It also provides a cab-forward design for added stability and weight distribution of the hopper.

* Pre-wet accessory sold separately

|

|

Optimized Spinner Channels

The ridges on the spinner ensure an even distribution of material throughout the spread arc. The spinner is 16” diameter and can spread salt up to 36’ and sand up to 24’.

|

|

|

STANDARD SPREADER FEATURES

|

Standard_Spreader_Features

Control Control

Enhanced dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions. Four standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency.

Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read. Its compact size compared to traditional controls fits easily into today’s modern truck cab designs.

|

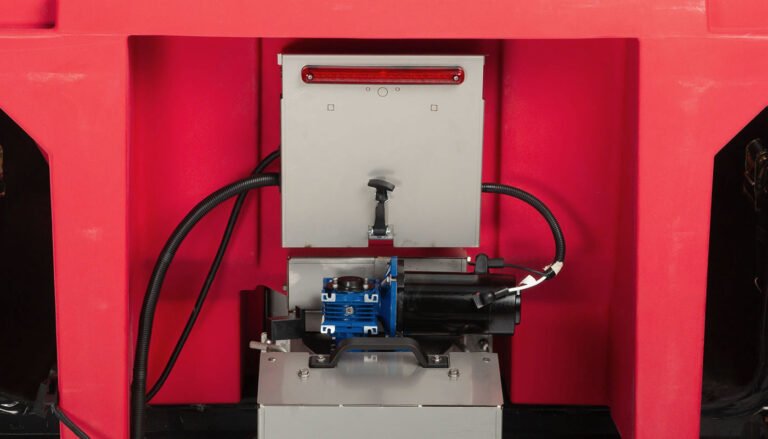

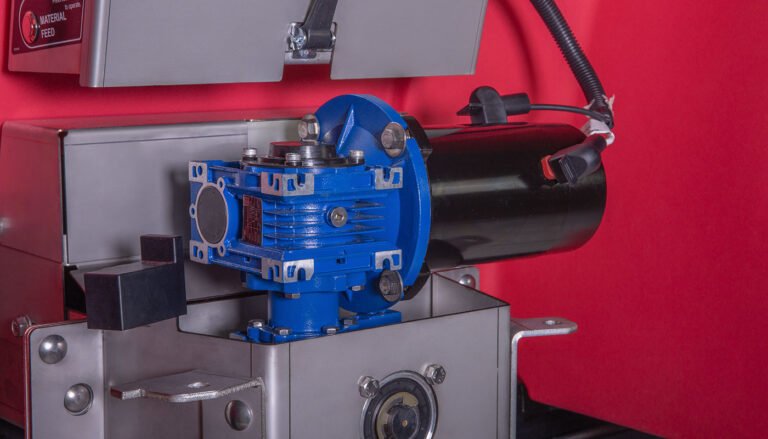

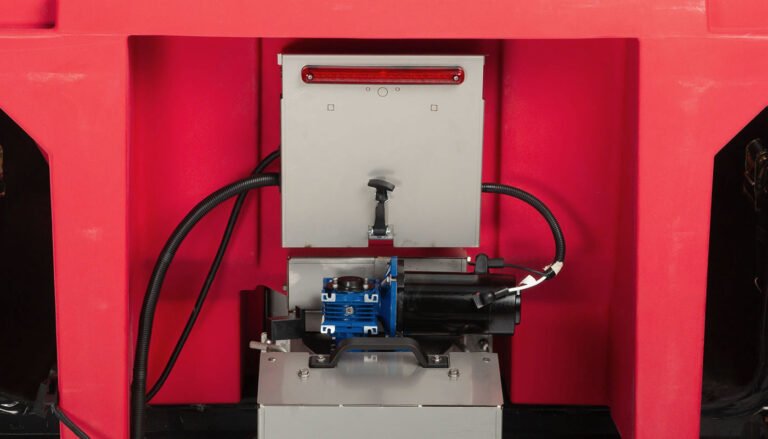

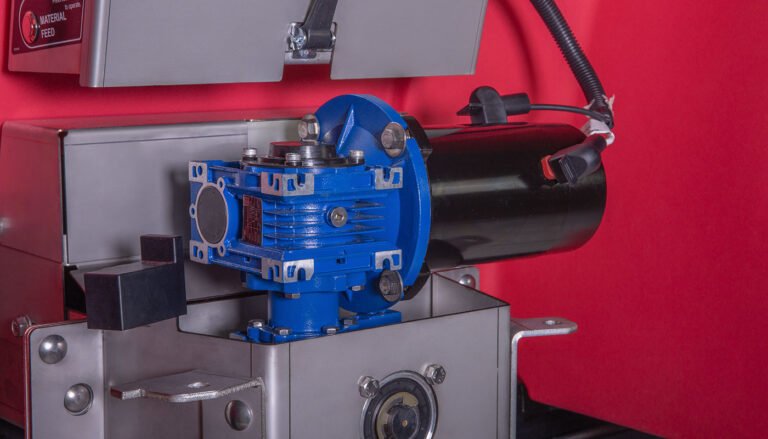

Electric Motor Electric Motor

The two high-torque 12-volt electric motors provide quiet, reliable and independent control over the conveyor and spinner mechanisms. The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion, while the conveyor motor is completely sealed from the elements.

|

Shutter Deflector Shutter Deflector

The easy-to-adjust circular shutter deflector allows directional spreading, providing optimal material control, while maintaining even coverage. For quick adjustments, simply move the convenient hand operated lever left or right to limit spread pattern to protect sensitive surfaces.

|

|

Accessory Integration & Knock Outs

Conveniently connect accessories directly to the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the truck. Hoppers feature knock-out holes for plug-and-play integration of certain accessories.

|

|

|

LITERTURE

|

|

|

Control

Control Electric Motor

Electric Motor Shutter Deflector

Shutter Deflector