Full Length HELIXX Design and Multi-Dimensional Tub

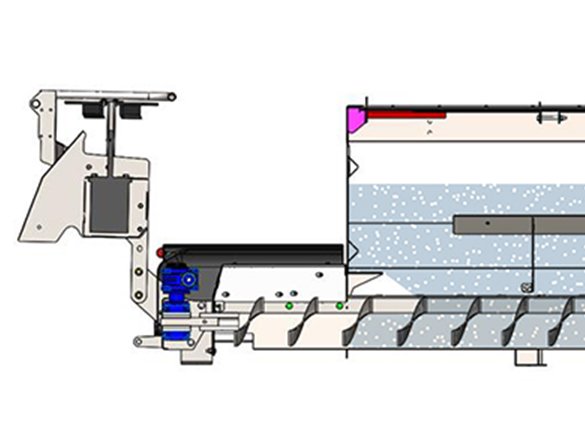

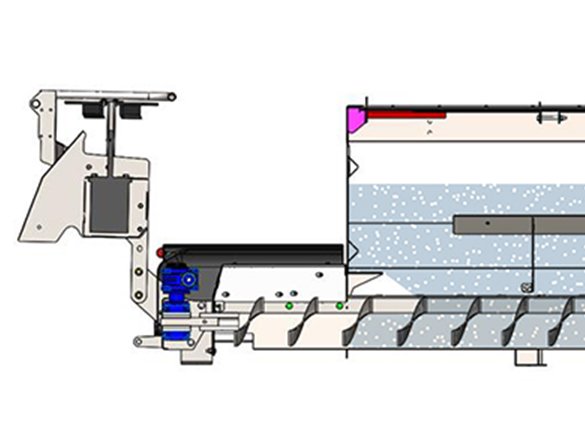

The HELIXX runs the entire length of the hopper with variable flights, promoting even unloading of material. Steel tub walls feature multiple angles and have a step built into the tub/sill joint for better material flow. |

Advanced Salt Delivery

The patent-pending corkscrew – or “helix” – design of the HELIXX material delivery system is optimized for efficient and cost-effective use of salt and was designed to operate in the target range for salt spreading best practices. The innovative design helps prevent clogs and delivers a material flow superior to traditional augers. |

Cab Forward Design Cab Forward Design

The cab forward hopper delivers better payload distribution to reduce stress on the vehicle and prevents leakage/spilling when transporting. |

Material Leak/Spill Prevention Material Leak/Spill Prevention

The HELIXX system extends beyond the hopper and into the patented pre-wet mixing chamber to help prevent leaking/spilling during transport while providing an ideal location for pre-wetting material. |

Stainless Steel Construction Stainless Steel Construction

Hopper and frame are constructed of corrosion-resistant stainless steel. The frame features a unique leg and sill design to form a ridged backbone structure for greater durability. |

Chute Baffle System Chute Baffle System

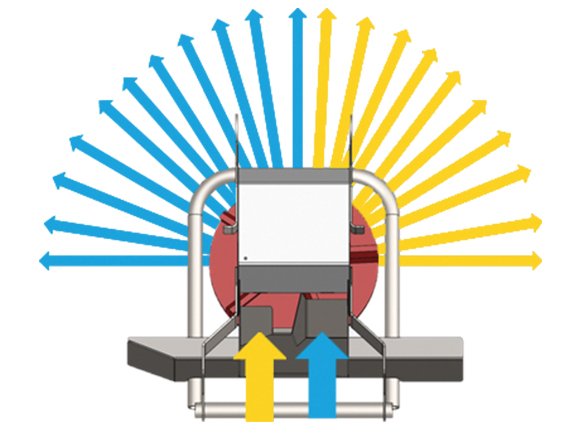

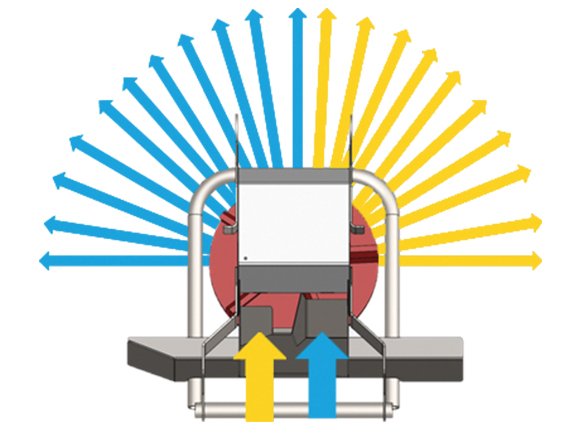

Baffles within the chute direct material to key areas on the spinner resulting in a remarkably even and consistent spread pattern, as well as reducing material directed back at the vehicle. |

Flip-Up/Removable Chute Flip-Up/Removable Chute

Remove a single pin to flip-up the chute, or two pins to take it off entirely, for easy hitch access and more flexible storage. Molded spinner plug must be removed when flipped for dumping. |

Inverted V Inverted V

Baffle that attaches within the tub that helps to keep material off of the HELIXX system to help maximize flow of compacted materials. |

Vibrator Vibrator

Attached to structural cross member, it vibrates the entire unit (tub and sill) to maximize flow of bulk materials. |

Dual Variable-Speed Control Dual Variable-Speed Control

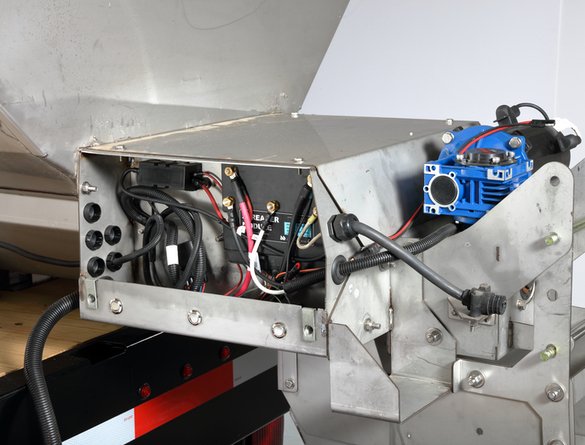

Allows for variable control of spinner and HELIXX speeds for precise material delivery at both a low or high output. Features auto reverse and integrates with accessories (including pre-wet and direct liquid application). |

Dump Switch Dump Switch

Rear-mounted dump switch allows operators to quickly dispose of spreading materials left in tub/material control chamber. |

Simple Installation Simple Installation

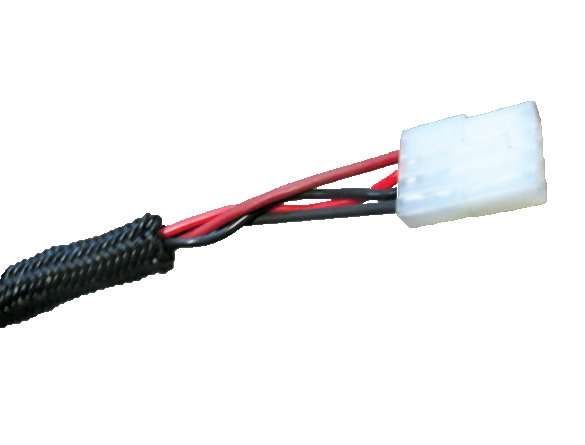

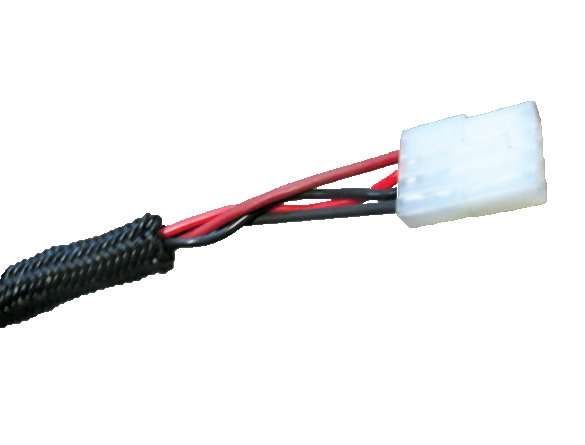

Only requires a single 4-pin wire routed into the cab to install the compact control. |

Spinner Height Adjustment Spinner Height Adjustment

Three spinner height adjustments allow spreaders to achieve a consistent spinner height of 18 to 22 inches off the ground, regardless of vehicle type (Standard on 11920, 11930 and 11940 models). |

Top Screen Top Screen

Top screen ensures material that enters the hopper is consistent size by breaking up any large clumps and filters out large debris to ensure proper operation. |

FLEET FLEX FLEET FLEX

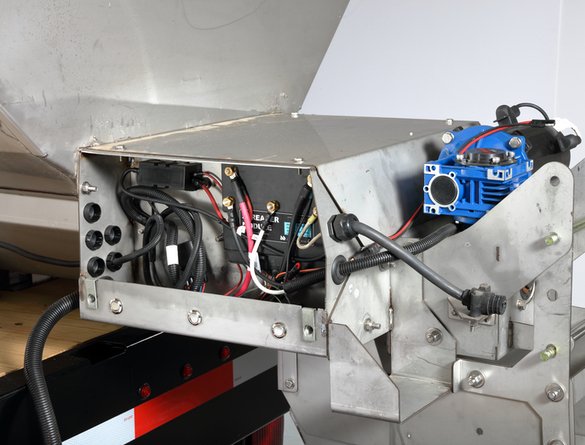

The FLEET FLEX electrical system provides a consistent electrical platform and complete fleet interchangeability between all HELIXX spreaders. |

No-Blast Startup No-Blast Startup

For maximum material placement and control, the spinner doesn’t blast upon startup, instead starting at the desired speed setting on the dial. |

Rear-Mounted Gear Box Rear-Mounted Gear Box

Easy access to motors, drives and other key components maximizes serviceability. |

Fork Pockets Fork Pockets

For simple install and removal, fork pockets are integrated into the frame legs. |

Pre-Wet and Direct Liquid Application Pre-Wet and Direct Liquid Application

Spread, pre-wet or spray with one machine. By adding pre-wet tanks, a pump and a spray kit, these HELIXX hopper spreaders can not only pre-wet materials, but they can also be used for spraying brine directly onto the driving surface for anti-icing applications. The components offer simple plug-and-play installation, meaning a contractor can upgrade to pre-wetting or direct liquid applications at any time. |

Get Directions

Get Directions

Get Directions

Get Directions

Cab Forward Design

Cab Forward Design Material Leak/Spill Prevention

Material Leak/Spill Prevention Stainless Steel Construction

Stainless Steel Construction Chute Baffle System

Chute Baffle System Flip-Up/Removable Chute

Flip-Up/Removable Chute Inverted V

Inverted V Vibrator

Vibrator Dual Variable-Speed Control

Dual Variable-Speed Control Dump Switch

Dump Switch Simple Installation

Simple Installation Spinner Height Adjustment

Spinner Height Adjustment Top Screen

Top Screen FLEET FLEX

FLEET FLEX No-Blast Startup

No-Blast Startup Rear-Mounted Gear Box

Rear-Mounted Gear Box Fork Pockets

Fork Pockets Pre-Wet and Direct Liquid Application

Pre-Wet and Direct Liquid Application Bulk Salt

Bulk Salt Bagged Rock Salt

Bagged Rock Salt