Get Directions

Get Directions

Get Directions

Get Directions

Western

Westernplow Striker® Compact 0.7 cu yd

-

ID # 35002124

- Back ID:35002124

- Book a Demo

- Get Directions

|

THE RIGHT SIZE FOR THE JOB The WESTERN® Striker® 0.7 and 0.35 cu yd stainless steel hopper spreaders offer the features and accessories that give you the performance, capabilities, and efficiency of larger WESTERN Striker hopper spreaders, but in a more compact size that’s better suited to handle smaller spaces and jobs. This salt and sand spreader has been designed to provide excellent material flow and delivery to the spinner. |

|

The low-maintenance, stainless steel, riveted construction provides durability for long-life and protection against stress. |

|

The Striker™ hopper spreader is designed with FLEET FLEX technology for easy interchange between electric hopper spreaders without having to change the wiring or the controls. It provides easy operation, increased reliability, simple wiring and easy installation. Additionally, accessories automatically integrate into the control for easy plug ‘n’ play. |

|

One of the widest in the industry, the 15½” pintle chain conveyer delivers reliable, smooth, and consistent material flow to help reduce bridging. The corrosion-resistant stainless steel conveyor housing provides added protection and reliability. |

|

An extra large 12″ polyurethane spinner delivers a spread pattern of up to 30′ and provides long-lasting, corrosion-free performance. *0.7 cu yd hopper shown |

|

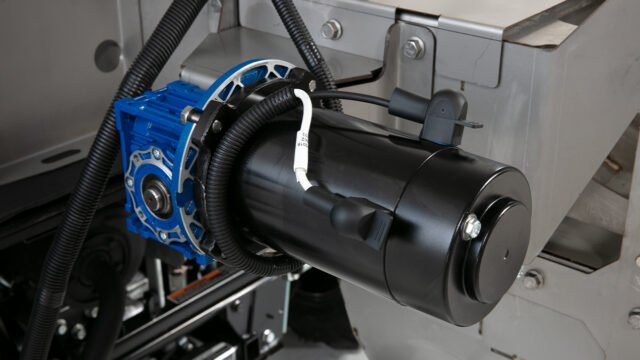

A fully enclosed 12-volt electric, ⅓ HP motor is mounted inside a sealed housing, protecting it from corrosion.

|

|

Enhanced dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions. Four standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency. Easy-to-understand, digital self-diagnostics alert the operator when the hopper is empty or when adjustments are needed, and LEDs make the controls easy to read. Its compact size compared to traditional controls fits easily into today’s modern UTV cab designs. |

|

Located at the rear of the hopper, two dump buttons run the conveyor for easily unloading excess material. Controlled by a third button, an accessory work light can be attached to illuminate the area at the rear of the spreader for better visibility when operating the dump buttons or working at the back of the hopper. |

| Full Line Brochures | Download |