Get Directions

Get Directions

Get Directions

Get Directions

Western

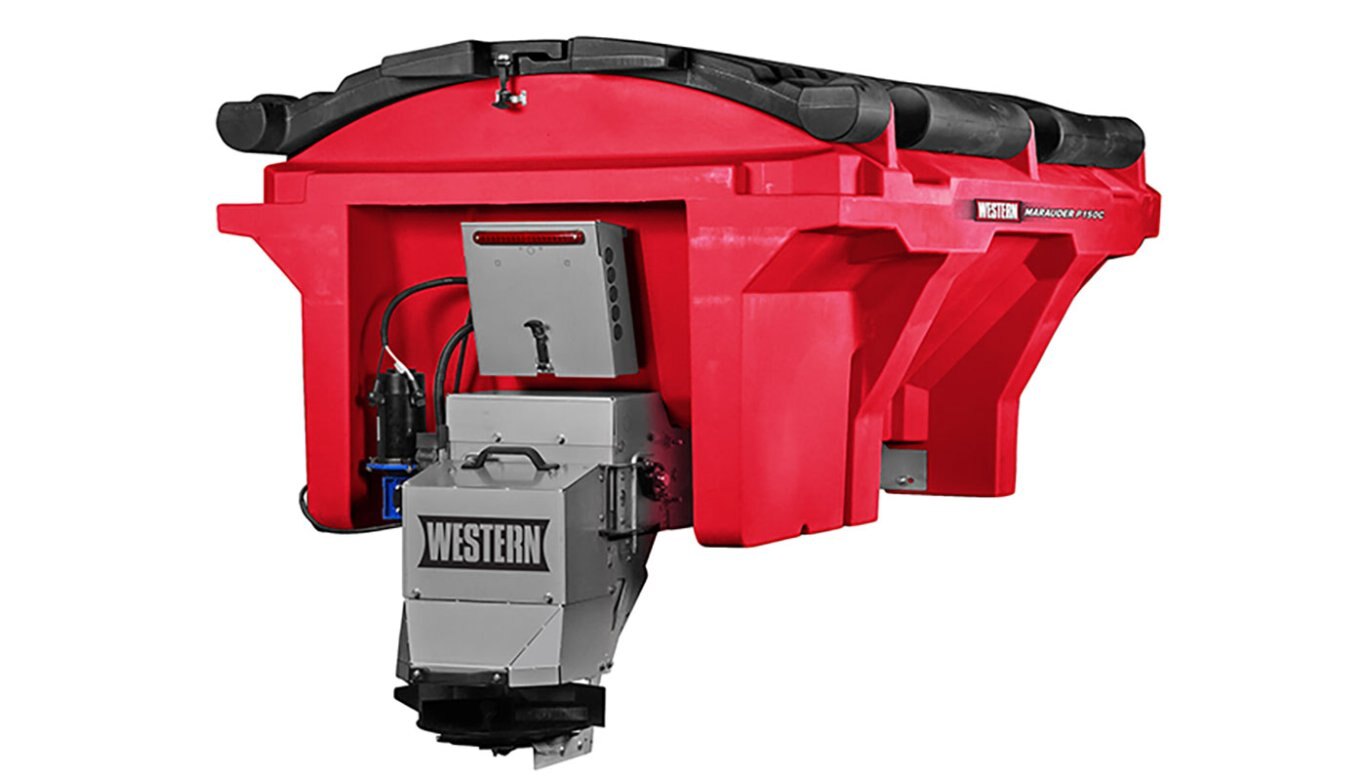

Westernplow MARAUDER™ POLY P220C

-

ID # 37952925

- Back ID:37952925

- Book a Demo

- Get Directions

READY FOR ANY STORMWhen the snow is flying and temperatures are plummeting, you need to be as efficient as possible. The MARAUDER line of hopper spreaders expands to give you the options you need to maximize efficiency. Corrosion-resistant polyethylene models with your choice of pintle chain or the ALL-NEW HELIXX™ auger delivery system are added to the MARAUDER line for more options to fit your operation’s needs. |

|

Polyethylene Construction & GeometryResist the corrosive environment of de-icing with polyethylene construction. Lightweight, yet highly durable, these hoppers are built to last. The molded polyethylene tub geometry is optimized for better material flow. This allows for a smoother, even flow that prevents materials from getting stuck. |

|

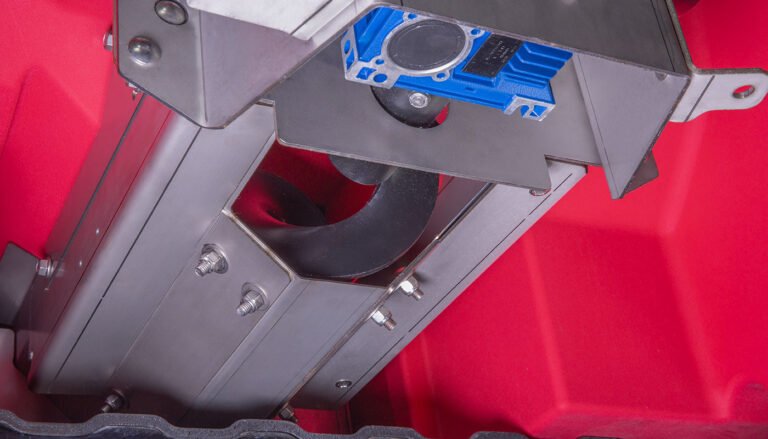

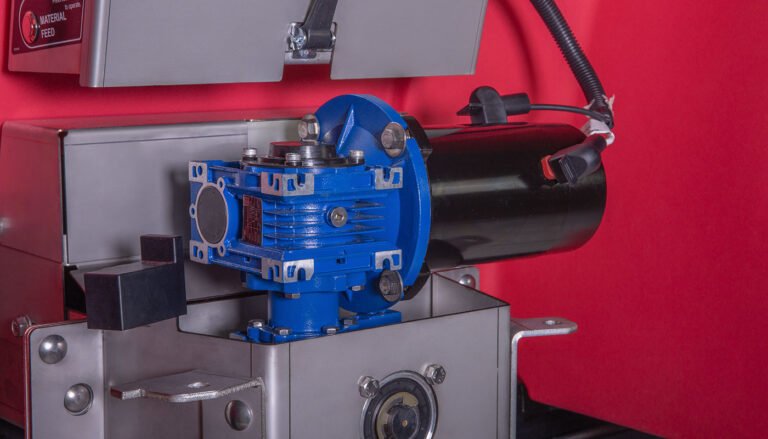

HELIXX™ Auger TechnologyPatented corkscrew material delivery system is optimized to operate in the target range for rock salt spreading best practices. The auger has multiple pitches to help promote smooth, even material flow from the hopper and prevents bridging. The shaftless technology reduces drag on the motor and reduces the overall load on the electrical system. * Auger Models Only (P150A & P220A) |

|

Pintle Chain ConveyorThe large conveyor delivers reliable, smooth, and consistent material flow for heavy, dense materials (like sand and 50/50 mix) while reducing bridging. * Chain Models Only (P150C & P220C)

|

|

Interlocking Poly LidsStandard lids have molded channels for moisture runoff. Pockets at the end of the lid allow a 2×4 to be inserted for leverage while opening. |

|

Stand on EndSpecial design allows the hopper to stand on end for easier storage in the off-season and easier installation into the truck bed. Simply remove the two pins, unplug it, and take off the chute before standing up the hopper.

|

|

Extended Material Delivery & Pre-Wet ChamberA material delivery extension reduces leaking/ spilling during transport and leads into the patented pre-wet mixing chamber. It also provides a cab-forward design for added stability and weight distribution of the hopper. * Pre-wet accessory sold separately |

|

Optimized Spinner ChannelsThe ridges on the spinner ensure an even distribution of material throughout the spread arc. The spinner is 16” diameter and can spread salt up to 36’ and sand up to 24’. |

|

|

|

|

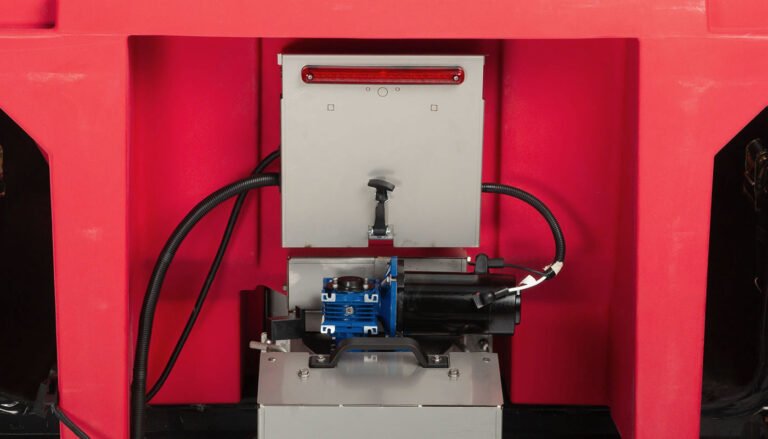

Accessory Integration & Knock OutsConveniently connect accessories directly to the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the truck. Hoppers feature knock-out holes for plug-and-play integration of certain accessories. |

| MARAUDER™ | Download |

Control

Control Electric Motor

Electric Motor Shutter Deflector

Shutter Deflector